METAL

DUCT

CONSTRUCTION STANDARDS:

We adhere to industry-leading construction standards such as:

• SMACNA HVAC duct construction standard for metal and flexible ducts.

• DW/144: Specification for sheet metal ductwork for low, medium, and high pressure velocity air systems.

• IS 655: Standard for metal air ducts used in air-conditioning and ventilation.

Unless otherwise specified, our ducting systems conform to the SMACNA standards.

RAW MATERIAL:

Our supply of duct profiles is crafted from lock-forming grade galvanized material in compliance with SMACNA standards. The raw material utilized is in coil form with a width of 1250mm. Additionally, alternative materials such as aluminum, Galvaluminum, or stainless steel can be employed based on specific project requirements.

DUCT CONNECTORS AND ACCESSORIES:

We manufacture a comprehensive range of transverse duct connectors, including flanges and cleats, along with associated hardware. These components are zinc-coated to ensure durability and longevity.

FABRICATION STANDARDS:

Our fabrication process adheres to stringent standards set by SMACNA. Utilizing advanced computer programs such as Fabrication CAMduct and CAMmep, we produce various duct profiles, including straight pieces, tapers, elbows, branches, shoe pieces, collars, and terminal boxes. Our state-of-the-art machinery ensures both high-quality production and efficient supply.

KEY MACHINERY AND PROCESSES:

U Shape Auto Duct Line 5: This machinery is primarily designed for TDF/angle steel/C-shaped flange forming, with a daily processing capability of 1000-2500 square meters. It automates multiple processes including uncoiling, leveling, beading punching, shearing, locking, and forming TDF/angle steel/C-shaped flanges.

Spiral Duct Machine: Our specialized spiral ducting machine creates superior airflow, noise reduction and energy-efficient spiral ducts for HVAC systems.

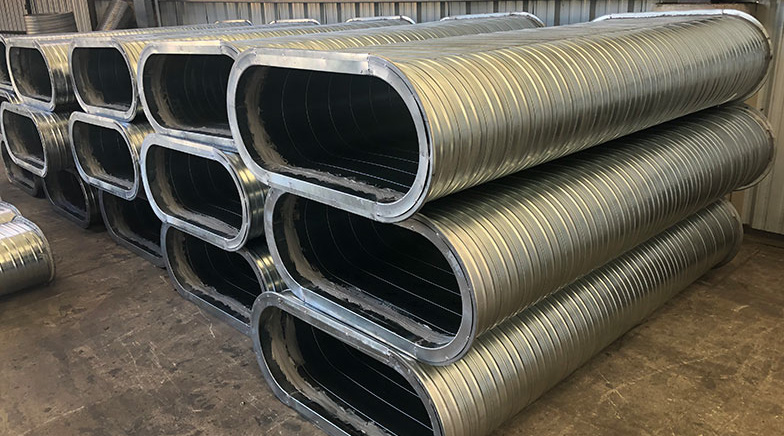

Oval Duct Machine: Operated by a full hydraulic system, the Oval Duct Machine expands round ducts, offering an extended lifespan and easy maintenance.

Coil Line: Our coil lines ensure precise location of longitudinal seams and provide necessary beading for duct rigidity and low leakage characteristics.

Plasma Machine: CNC profile cutting machines are employed to fabricate duct transformation pieces with utmost accuracy.

Roll Forming Machines: All edges are processed on roll forming machines to form longitudinal seams, transverse joints, and roll-bending for turning up edges.

Transverse joints adhere to TDC type flanges or equivalent systems.

FLAT OVAL DUCTS

RECTANGULAR DUCTS